We help our customers take their electrolyzer technology to the next level

There is a global commitment to decarbonize the world’s energy system and the advancement of green hydrogen through water electrolysis is taking center stage. The need has never been greater and it’s a mission that will take more than one idea, technology, or company to succeed.

SKYRE is playing a central role in advancing water electrolysis at scale. SKYRE specializes in every aspect of electrolyzer commercialization, from research and manufacturing, to supply chain development and quality assurance. Our team collectively holds over 50 U.S. and international patents and has 4 decades of experience, having built and delivered over 30,000 systems for 700 commercial, military, and aerospace customers. Our experience is unparalleled in cell stack design, testing, systems engineering, catalyst and materials development, manufacturing, and more.

Let us show you how we can seamlessly collaborate with you, and move you from lab to scale.

How can we help you?

-

Originally developed for NASA and the U.S. Navy as the critical element of life support systems for closed environments - such as those found in spacecraft and submarines - our proven technology is keeping people alive in the harshest environments. Failure is not an option and the design and construction of our systems reflect that same rigor.

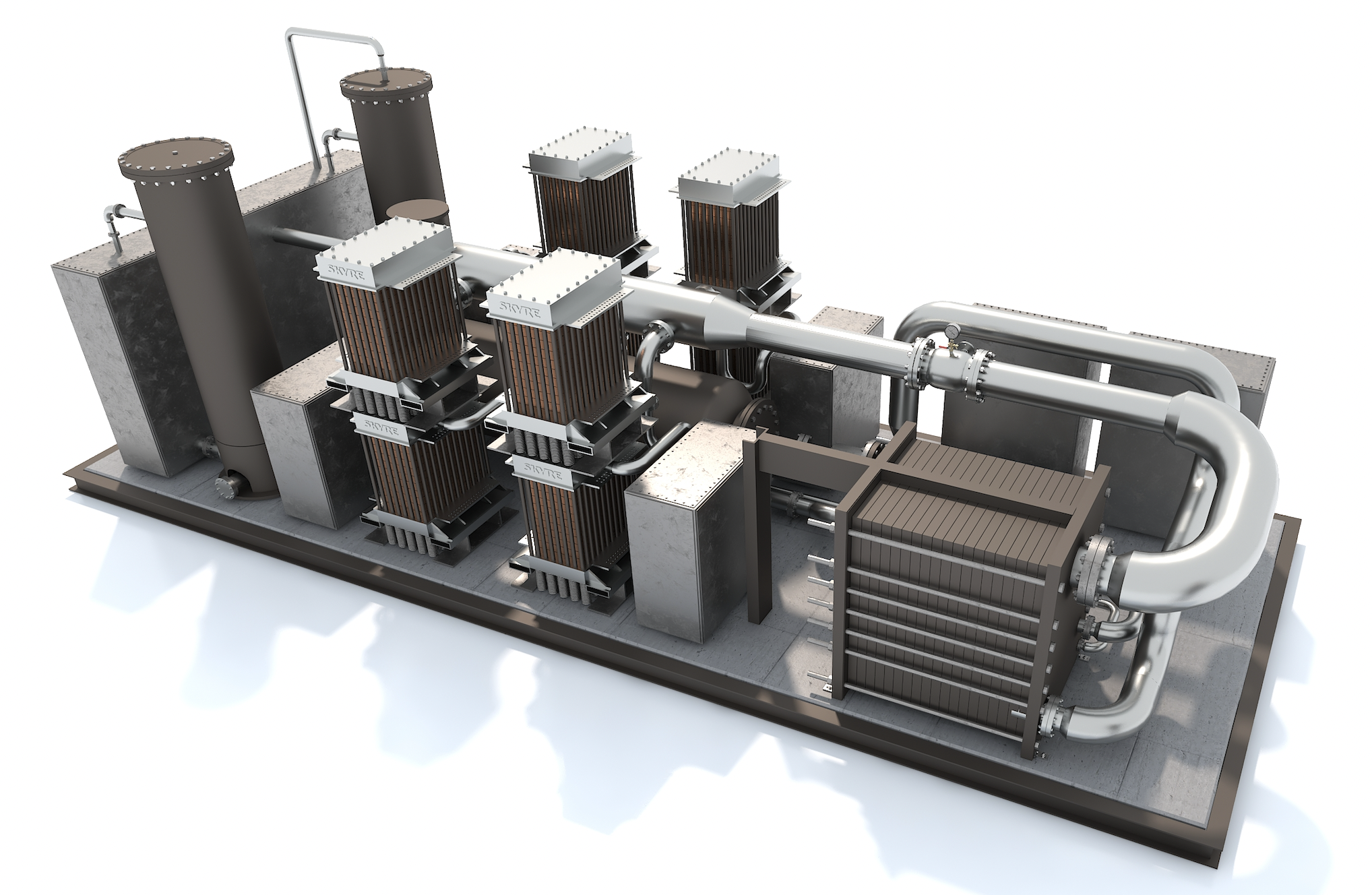

SKYRE has a patented, novel, scalable electrolyzer design that eliminates manufacturing limitations and the tolerances associated with typical hydrogen production hardware.

-

SKYRE will build your electrolysis system by leveraging our innovative and distinct electrolyzer technology - including high pressure generation, built to cost, with high purity gas output, high efficiency, reliability, and scalability.

Send us your specifications to get started.

-

SKYRE is unparalleled in cell stack design, testing, systems engineering, catalyst and materials development, manufacturing, and more.

Our expertise includes:

System & Cell Designs

Controls and Software

Hardware Scalability

Ability to Contend With Impurities

Adaptation to Multiple Applications

Safety and Safety Analysis

Market Analysis

Test Stand Design and Construction

Automated Testing

Let us show you where we can make a difference.

-

SKYRE has full capability to make electrolyzer components including the following:

Catalyst Processing

Membrane Processing

Membrane/Electrode Assembly

Flow-Field Fabrication

High Pressure Assembly

Separations

Sealing

Insulating and Conductive Coating

info@skyre-inc.com

111 Roberts Street

Suite J

East Hartford, CT 06108

Contact us.

About Electrolyzers

-

An electrolyzer is a unit that generates hydrogen through the chemical process electrolysis. Implementing electrolysis, SKYRE uses electricity to split water into hydrogen and oxygen - providing a clean stream of hydrogen. SKYRE scales electrolyzers for a variety of uses, from small operations to large industrial applications.

-

Also called renewable hydrogen, green hydrogen is generated using electrolysis within a unit called an electrolyzer. Electrolysis is the chemical process of using electricity to split water into hydrogen and oxygen. The key to green hydrogen is that the electricity used is derived entirely from renewable energy sources like wind and solar. Green hydrogen is one of the leading alternatives to fossil fuels and a key element in the world’s shift to decarbonization.

-

Hydrogen has become a leading alternative to fossil fuels as the world rushes to decarbonize. Hydrogen is the most abundant element on the planet, but currently the majority of hydrogen is made using natural gas, flooding the air with carbon dioxide. Using electricity derived from renewable sources like wind and solar, SKYRE is able to generate green hydrogen, an imperative to making hydrogen the fuel of the future.